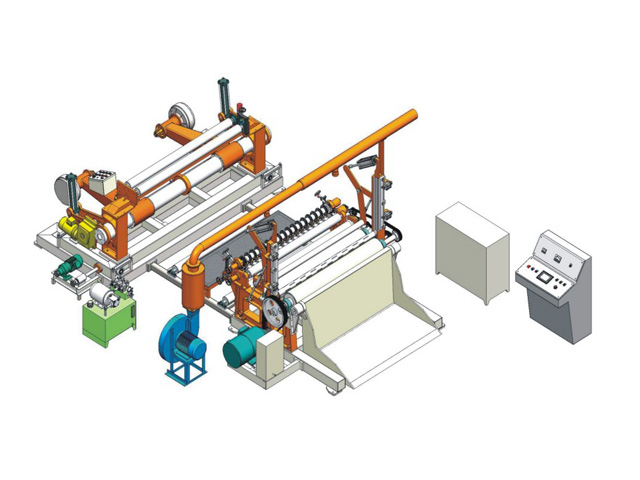

| Paper Roll Width: | 1600mm(standard) |

| Paper Roll Diameter: | 1500mm(max) |

| Rewind Diameter: | 1500mm(max) |

| Slit Width: | 50mm(min) |

| Main Motor: | 18.5Kw |

| Cross Beam Moving Motor: | 1.1Kw |

| Parent Roll Lifting Motor: | 1.1Kw |

| Clamping Motor: | 2.2Kw |

| Waste Edge Blower Motor: | 5.5Kw(matching) |

| Automatic Web Guide System: | 1 set(matching) |

| Machinery Speed: | 380m/min |

| Parent Roll Clamp: | 1 set(3INCH) |

| Digital Tension Control: | 1 set |

| Magnetic Braking Device: | 2 sets |

| Paper Reels Separation System: | 1 set |

| Separated Electric Operating Box: | 1 set |

| Surgent Electric Operating Box: | 1 set |

| Overall Size: | 5560 x 4000 x 2050mm |

Specifications

FZ-G-NC Paper Slitting Rewinding Machine:

1.Unwind O.D.:1200mm

2.Rewind O.D.: 1200mm

3.Slitting width:50-1600mm

Machine Functions:

l Equips lifting and clamping mechanical arms to lift, clamp and adjust the jumbo paper roll, improving efficiency and reducing manual;

l Adopt touch-screen panel (Taiwan WeinView) and special-purpose operating system, easy to operate.(Display in English)

l Adopt single -shaft surface rewinding mold, reduce compressive strength requirement, ensure better rewinding effect;

l Can get a good slitting edge, helpful to control tube spiral gap in paper tube winder machine;

l Digital control tension control system, do not need manual adjusting, ensure better slitting effect;

l Adopt Japanese NSK bearings, all driving rollers be balance adjusted, have better driving effect.

l Automatic rewind paper rolls separate device- rubber bent roller: it makes rewind paper rolls separate automatically, avoid conglutination phenomenon;

l Equipped with Paper Waste Edge Blower device: collect slitter paper edge, break it, and transfer to a certain place, easier for cleaning.