| Inside Diameter: | 40-160mm |

| Parent Tube Length: | 1600mm |

| Cut Length: | min 10mm |

| Wall Thickness: | 3-15mm |

| Cutting Precision: | (+-)0.3mm |

| Knife Carriage Moving Speed: | 500mm/sec |

| Working Air Pressure: | 0.6Mpa |

| Operator: | 1 person |

| Machinery Speed: | 1 cycle/sec (speed changes in different tube specification) |

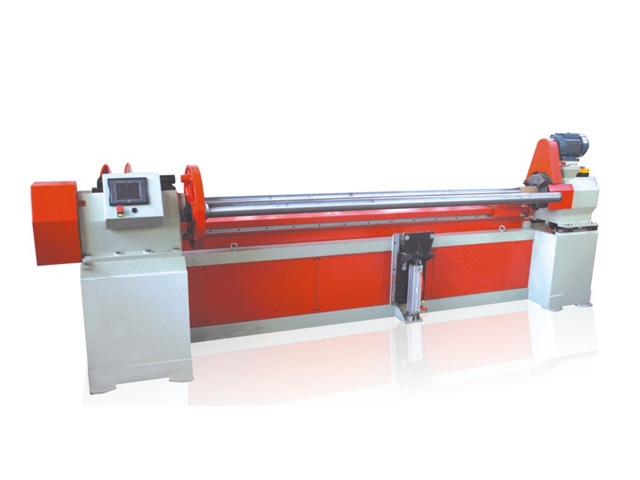

Specifications

SJQ-2D full automatic double shatf paper core cutting machine:

1. ID:40-160mm

2. Thickness:3-15mm

3. Recut length:10-1600

A. Machine main functions:

l Adopt micro-computer to set recut length,high precision;Adjust data conveniently on touch screen;

l Adopt human-machine interface and specialized operation system,easier to operate;

l High mechanism processing accuracy,the tolerance of recut tube length can be controlled within +/- 0.3mm;

l Tube is cut by tungsten steel circular knife;

l Manually tube loading and unloading;

l No need to adjust knives distance,only need to put in required data on touch-screen,saving time and avoiding tube waste caused by inaccurate manual knives-adjustment;

l Knife rotates a certain angle after every cut,reducing knife damage, prolonging knife’s using life;

l When knife is partly broken, still can cut, just turn an angle then fasten it;Prolong knife using life;

l Knife adjusting part is equipped with a precise dial gauge,ensuring knife touches mandrel in a exactly position; Reduce damage to mandrel cause by knife touch;

l Tube rotates while knife does not rotate.Smooth cut surface comes out by the friction between knife and rotating tube;

l Tube rotates while mandrel does not rotate.Reduce damage to knife and mandrel,prolonging using life;If mandrel also rotates in cutting,it will form a cutting circle line on mandrel;While mandrel doesn’t rotate,only a cutting point on mandrel;

B. Main parts material and instruction

l Machine installed cover and door are made of cold plating sheet;

l Machinery frame is welded by heavy channel steel and iron sheet.

l Tungsten steel circular knife.