| Inside Diameter: | 40-250mm |

| Wall Thickness: | 1-15mm |

| Tube Length: | 1-4m |

| Machinery Speed: | 1-20m/min |

| Main Motor: | 22Kw |

| Working Air Pressure: | 0.6Mpa |

| Cutting Pattern: | two circular knives |

| Length control model: | HLC |

| Glue Unit: | PL type |

| Paper Reel Stand: | ZT type |

| Operators: | 3-5 persons |

| Overall Size: | 6900 x 2050 x 2300mm |

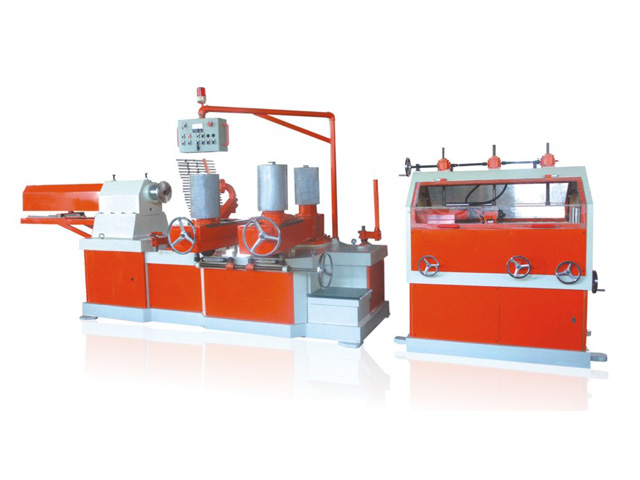

LJT-4DHLC Paper Pipe Spiral Winder:

1.Servo motor

2.Cut synchronize with machine speed.

3.ID:50-200MM

4.THICKNES:1-15MM

Machine Functions:

l Adopt microcomputer set in-line cut length, more accurately; Touch screen convenient for data adjusting;

l Adopt human-machine operation interface, more convenient for operation;

l Mechanical loading paper reels, reduce labor force;

l Paper ply tension control system, cylinder press paper ply firmly, can adjust tension freely;

l Supply gluing pots and pressure tension control system; adopt single or double side gluing depends on tube required strength;

l Flanged shaft with flexile design, suit with tapered mandrel, can do fine-turning to tube inside diameter.

l Automatic alarm when bottom-ply broken, and stop machine; avoid glue adhere to mandrel and difficult to clear away;

l Tube in-line cutting moving speed controlled by servo motor, tracking with tube production speed to be synchronously;

l Machine frame is with the anti-deformation treatment, ensures machinery running stability and working precision.

Note: above are just parts STANDARD technical parameters for reference; For confirm the most suitable mold, please tell us your practical parameters and requirements by email, then we will give you our advise and machine details, thanks.