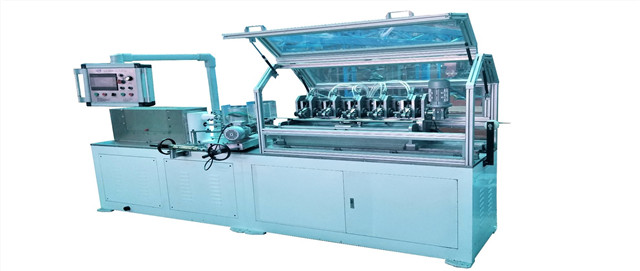

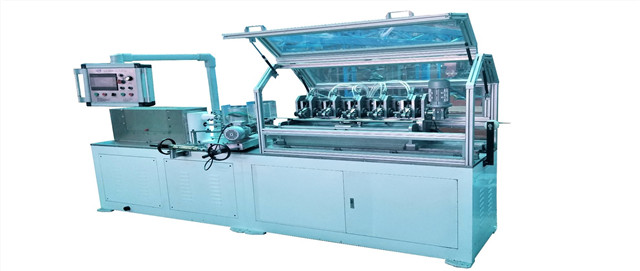

| Tube ID | Ø 5 mm – Ø 12mm

|

Tube thickness

| 0.25 – 1mm

|

Machinery Speed

| 1 – 50 m/min

|

Cutting length

| 130 mm – 7,80 mm

|

Cutter set

| 5 SETS |

Main function:

l Adopt microcomputer to set cutting length, moreaccurate, touch screen is more convenient to adjust data.

l Adopt specialized human-machine operation interface,Pendant type operating panel, more convenient to operate.

l Automatic-alarm and machine-stop when bottom-ply isbroken; Avoiding glue adheres to mandrel and causing difficult to clear away.

l Integrate some paper reel stands incross-shape into unitary stand, that is to improve the stability of paper standand reduce floor space.

l Adopt roller gluing, low requirement topaper quality, less ground space, and can adopt double-side or single sidegluing according to compressive strength of paper core.

l Servo motor controls the moving speed of in-line cutting part, synchronouswith tube production speed.

l Cutting system adopts multi-knifecutting at same time, and can cut into 4 sections of short paper cores, andmake sure the precision of cutting, avoid the second-time cutting, save laborsand device.

l Cutting system equipped with one conveyor and output paper tube smoothly.Paper tube collecting device is equipped by customers.